Common Signs and Symptoms of a Malfunctioning Gas Furnace

A gas furnace is a critical component in many homes, providing warmth and comfort during the cold months. Get ahold of All-Ways Heating & A/C for affordable gas furnace repair . However, like any mechanical system, it can experience issues that may hinder its performance or even pose safety risks. Recognizing the common signs and symptoms of a malfunctioning gas furnace is essential for homeowners to take timely action and ensure successful repair. In this short essay, we will explore some of these indicators that suggest your gas furnace may need attention.

One of the most obvious signs of a problem is a lack of heat production. If you notice that your home isn't reaching the desired temperature or the furnace is blowing cold air, there could be an issue with the ignition system or pilot light. Modern furnaces have electronic ignitions that can fail, while older units with pilot lights might go out due to drafts or blockages in the system.

Another symptom is unusual noises coming from the furnace. Banging, whistling, or grinding sounds are not normal and could indicate various problems such as loose components, airflow obstructions, or motor bearings in need of lubrication.

An increase in energy bills without a corresponding rise in usage can also point to an inefficiently operating furnace. This inefficiency can result from clogged air filters that restrict airflow or a malfunctioning thermostat causing the system to run longer than necessary.

Frequent cycling — turning on and off more often than usual — should raise red flags as well. This behavior suggests overheating issues due to restricted airflow from dirty filters or obstructed vents; alternatively, it could signal problems with the thermostat or its connection to the furnace.

The presence of soot around the furnace register or streaks near venting pipes indicates incomplete combustion within your gas furnace. This not only reduces efficiency but also poses serious health hazards as it could lead to carbon monoxide leaks into your home's living spaces.

A strong odor resembling rotten eggs is another urgent sign you shouldn't ignore. Gas companies add this distinct smell to natural gas (which is otherwise odorless) as a safety measure for detecting leaks. If you detect this scent near your furnace, shut down your unit immediately and contact professionals for immediate inspection and repair.

Finally, if you spot water pooling around your furnace (and it doesn’t utilize condensation technology), there’s likely an issue with either the condensate drain being clogged up or another internal component failing which could potentially cause water damage over time.

In conclusion, recognizing these common signs and symptoms associated with malfunctioning gas furnaces allows homeowners to promptly address problems before they escalate into costly repairs or dangerous situations. Regular maintenance checks by qualified technicians are recommended to keep your heating system running efficiently and safely throughout its lifespan; however, knowing what warning signals look out for empowers individuals when unexpected issues do arise on their path towards successful gas furnace repair.

Safety Precautions Before Attempting Any Furnace Repairs

Prior to embarking on any repair journey for a gas furnace, it's imperative to recognize the significance of safety precautions. These measures are not just about protecting your own well-being; they also ensure that the furnace system remains secure and functional after the repair, preventing potential hazards such as gas leaks or fires.

One of the foremost precautions is ensuring that you have shut off the power supply to the furnace. This might involve turning off the electrical switch dedicated to the unit or disconnecting power at the circuit breaker box. Such a step wards off electric shock risks and prevents accidental activation of the furnace while you're working on it.

Equally essential is shutting off the gas supply.

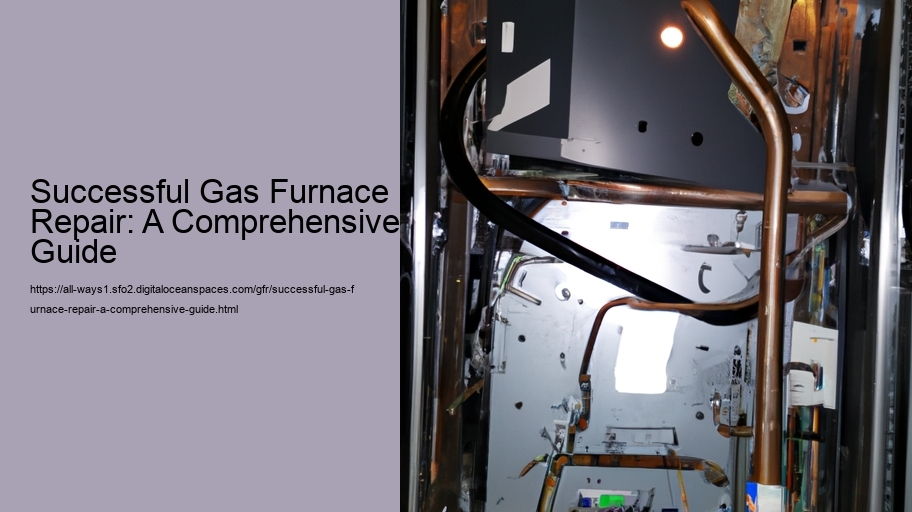

Successful Gas Furnace Repair: A Comprehensive Guide - furnace tune-up

- gas furnace maintenance

Before attempting repairs, reading through your furnace manual is wise—it provides specific instructions related to your model, which enhances safety and efficiency in handling repairs. If you've lost your manual, often manufacturers provide digital copies online.

Donning appropriate personal protective equipment (PPE) like gloves and eye protection can shield against cuts from sharp metal edges commonly found inside furnaces. Furthermore, having proper tools ready ensures not only effective but also safe repair procedures—using improper tools could damage components or lead to injuries.

Testing for carbon monoxide leakage before and after repairs is another critical step since CO is an odorless yet lethal gas that can be emitted by faulty furnaces. Installing carbon monoxide detectors around your home offers an additional layer of security.

Never hesitate to contact professionals if you are unsure about any steps involved in repairing your furnace. An expert technician can manage complex issues more safely and efficiently than an untrained homeowner.

In sum, when contemplating any sort of maintenance or repair work on a gas furnace, prioritizing safety cannot be overstated—it's integral for both human welfare and operational reliability of your heating system. By adhering strictly to these precautions before diving into any DIY fix-it tasks with your furnace, you’ll set yourself up for success while minimizing risks associated with such undertakings.

Troubleshooting Tips for Identifying Gas Furnace Issues

When it comes to maintaining a comfortable home during the chilly months, a properly functioning gas furnace is vital. However, like all appliances, gas furnaces can experience issues that may hinder their performance or even cause them to fail completely. For homeowners and repair technicians alike, being able to successfully identify and resolve these issues is crucial for ensuring warmth and safety throughout the winter season. Here are some troubleshooting tips that can aid in diagnosing common gas furnace problems.

Firstly, always prioritize safety before attempting any kind of troubleshooting or repair on your gas furnace. Make sure you turn off power to the unit before you begin examining it.

One of the initial steps in troubleshooting is checking whether the furnace is receiving power. This involves inspecting the circuit breaker or fuse box for any tripped breakers or blown fuses. If everything appears intact, proceed to check if the thermostat is set correctly and functioning as it should; sometimes, simply replacing batteries or adjusting settings can get your furnace running again.

If there's no issue with power supply and thermostat settings, listen for unusual noises coming from the furnace when it operates. Rumbling sounds could indicate unburned fuel in the combustion chamber—a potentially dangerous situation—while squealing might suggest a problem with the belt driving the blower.

A common issue many face with gas furnaces is a failure to ignite. This could be due to an obstructed flue, faulty ignition system, or problems with electronic components such as sensors which manage airflow and temperature within the unit. Ensure that pilot lights (if present) are lit and inspect igniters for wear or dirt accumulation that could prevent them from working correctly.

Inadequate heating is another frequent complaint which could stem from various sources including dirty air filters restricting airflow—replacing them regularly can often remedy this problem—or malfunctioning heat exchangers that compromise heating efficiency.

Should you notice your furnace frequently cycling on and off more than normal (short cycling), this erratic behavior may be due to an oversized unit for your space, incorrect thermostat calibration, or overheating components within the furnace itself.

Lastly, carbon monoxide leaks pose serious risks; therefore, make sure carbon monoxide detectors are installed near your furnace area and they function properly since CO leaks usually go undetected until they become hazardous.

For more complex issues such as those involving gas lines or internal mechanical failures, enlisting professional help from certified HVAC technicians is strongly recommended rather than attempting DIY repairs which could exacerbate problems or create new hazards altogether.

Successful Gas Furnace Repair: A Comprehensive Guide - oil to gas conversion

- furnace tune-up

- exhaust flue checking

Step-by-Step Guide on Repairing the Most Frequent Gas Furnace Problems

Successful Gas Furnace Repair: A Comprehensive Guide

As the temperature drops, the reliability of your gas furnace becomes increasingly crucial to ensure a warm and comfortable home. However, even the most dependable systems can encounter issues. Knowing how to tackle common problems can save you time, money, and discomfort. This essay provides a step-by-step guide for repairing frequent gas furnace troubles.

First and foremost, safety is paramount when dealing with any type of furnace repair. Make sure to turn off the power supply to your furnace before beginning any troubleshooting or repairs.

1. **Furnace Not Heating**: If your furnace isn't heating at all, check that it's receiving power by ensuring that the circuit breaker hasn’t tripped and that the power switch is on. Next, examine your thermostat settings to make sure it’s set to heat and that the desired temperature exceeds room temperature.

2. **Dirty Filters**: One of the most common issues impacting furnace efficiency is dirty air filters which restrict airflow and may cause the system to overheat. Locate your filter, usually found in the blower compartment or an attached filter rack, slide out the old filter and replace it with a new one matching its size and ratings.

3. **Faulty Ignition System**: If you have an electronic ignition system that isn’t working properly, first confirm if it’s a hot surface ignitor or an intermittent pilot light issue; then proceed according to manufacturer instructions – often simply cleaning or repositioning them can solve this problem.

4. **Thermostat Malfunctions**: Sometimes what seems like a furnace problem is actually due to a faulty thermostat. Ensure that it's securely attached to the wall without loose connections; also try opening up its casing (for non-digital models) and gently dusting inside using a soft brush.

5. **Blower Motor Problems**: Listen for unusual sounds suggesting blower motor issues such as squeaks or rattles indicating wear or lack of lubrication on older models with oil ports—add a few drops as needed following manual guidelines.

6. **Pilot Light Issues**: For furnaces with standing pilot lights, ensure that yours is lit; if not, follow your manual’s re-lighting instructions carefully while checking for drafts or blockages in vents which could be extinguishing it repeatedly.

7. **Heat Exchanger Concerns**: The heat exchanger should only be inspected by professionals due to risks including carbon monoxide leaks—so call an expert if you suspect any related issues like strange smells or soot around your register vents.

8. **Cycling Too Frequently**: Frequent cycling between on-and-off states might indicate an oversized unit but could also point towards something simpler like incorrect thermostat calibration or poor airflow from clogged filters mentioned earlier—investigate these first before consulting with technicians about potential resizing needs for your space.

9. **High Energy Bills**: Lastly, if you’re seeing spikes in energy bills without clear explanation—after ruling out obvious reasons like increased usage during colder months—it may signal inefficiencies within your system requiring more thorough assessments from experienced professionals who can identify less obvious culprits after conducting diagnostic tests.

Regular maintenance checks are essential in avoiding some of these common problems; however when they do occur having this knowledge empowers homeowners with initial steps they can take towards rectifying them prior reaching out for professional assistance thereby mitigating both inconvenience caused during cold spells along with potentially hefty repair bills down line making successful gas furnace repair approachable task anyone willing learn basics behind their home heating system operations.

When to Call a Professional: Recognizing Jobs Out of Your Skill Range

Successful Gas Furnace Repair: A Comprehensive Guide - When to Call a Professional: Recognizing Jobs Out of Your Skill Range

Tackling home repairs can be satisfying and cost-effective for those with a do-it-yourself spirit. However, when it comes to repairing a gas furnace, there are clear boundaries between tasks that are suitable for handy homeowners and those that should be left to professionals. Understanding when to call in the experts is not only crucial for ensuring the job is done correctly but also for maintaining safety.

Gas furnaces involve intricate electrical components, combustible gases, and high-efficiency technologies that require an expert's touch. Simple maintenance tasks like changing filters or cleaning dust from accessible areas can typically be handled by homeowners. However, recognizing jobs out of your skill range is paramount.

One of the first signs you need a professional is when you're faced with issues related to the internal components of your furnace, including pilot lights, electronic ignitions, heat exchangers, or condensate drains. If these parts malfunction or show signs of wear and tear, they could lead to hazardous conditions such as gas leaks or carbon monoxide buildup if not properly addressed.

Moreover, if your furnace emits unusual noises like banging, whining or grinding sounds; if there's inconsistent heating or no heating at all; if there’s a yellow rather than blue flame; or if you smell gas around the unit—these are red flags signaling that it’s time to step back and consult a professional technician.

Another scenario where expertise is necessary involves diagnosing and fixing problems with advanced control systems such as thermostats and zone controls. While some thermostat issues can be resolved through troubleshooting steps provided in user manuals—a non-responsive system or complex wiring problems will likely demand specialized knowledge.

Additionally, any work that requires handling refrigerants (for furnaces combined with air conditioning units), adjusting gas pressure, replacing major components like blowers or motors falls strictly within professional territory due to both technical difficulty and legal requirements regarding certification.

Also consider calling in pros when it comes down to preventive measures. Yearly inspections and tune-ups should ideally be performed by someone who can identify early signs of trouble that untrained eyes might miss—thus avoiding costly breakdowns down the line.

Lastly, local building codes often stipulate permits for significant furnace repairs or replacements which must conform to strict standards—another reason why hiring certified technicians becomes essential since they are familiar with these regulations.

In conclusion, while it’s admirable to attempt certain household fixes on your own—when it comes to successful gas furnace repair—you must recognize when a job reaches beyond DIY territory into professional terrain. Doing so ensures not only the longevity and efficiency of your heating system but more importantly—the safety and well-being of all occupants in your home. exhaust flue checking Keep this guide in mind before rolling up your sleeves: some projects are best entrusted to seasoned hands equipped with the right tools, training,and certifications necessary for tackling complex heating challenges.

Maintenance Tips to Prevent Future Gas Furnace Repairs

Successful gas furnace repair not only involves addressing current issues but also implementing preventative maintenance to reduce the likelihood of future problems. Proactive care can extend the lifespan of your heating system, improve its efficiency, and save you money on unexpected repairs. Here's a short guide with some essential maintenance tips to help prevent future gas furnace troubles.

First and foremost, regular cleaning is key. Dust and dirt can accumulate in your furnace, which can cause it to work harder than necessary and lead to wear and tear. Make sure to change or clean the air filters every one to three months, depending on usage and type of filter. A clean filter ensures proper airflow, reduces energy consumption, and maintains good indoor air quality.

Secondly, inspect the thermostat regularly. It's the brain of your heating system; if it's not functioning correctly, neither will your furnace. Check that it's properly calibrated and that there aren't any loose connections or wires. Sometimes a simple battery replacement is all that’s needed for electronic thermostats.

Thirdly, keep an eye on your furnace's blower belt (if applicable). A frayed or cracked belt can lead to inadequate operation or even a breakdown. Inspect it periodically for signs of wear and replace it as necessary.

Fourthly, ensure that vents throughout your home are never blocked by furniture, rugs or drapes. This allows for proper airflow distribution which keeps your system from overworking itself.

Fifthly, listen for strange noises coming from the furnace like banging, grinding or whistling sounds. These could indicate mechanical problems that may require professional attention before they worsen.

Sixthly, have professional inspections annually by a certified HVAC technician who can perform more complex checks like ensuring the heat exchanger is free from cracks (which could be dangerous), verifying flue pipes are properly vented outside without obstruction, checking gas connections for leaks and making sure electrical components are in good condition.

Seventhly, pay attention to the burner flame if you have access through observation ports – it should burn blue with little yellow at the tip; an inconsistent or yellow flame might suggest dirty burners or a potentially dangerous condition such as carbon monoxide presence.

Lastly but importantly – practice safety first! If you smell gas around your furnace or suspect any immediate danger such as a gas leak — don’t attempt repairs yourself — evacuate immediately and call professionals from a safe location.

In conclusion, maintaining a gas furnace isn't just about fixing what breaks; it's about taking ongoing steps to ensure reliability and efficiency while preventing future repairs where possible. By following these maintenance tips diligently you’ll create peace of mind knowing that your heating system is running safely at optimal performance levels throughout those cold months when you need it most.