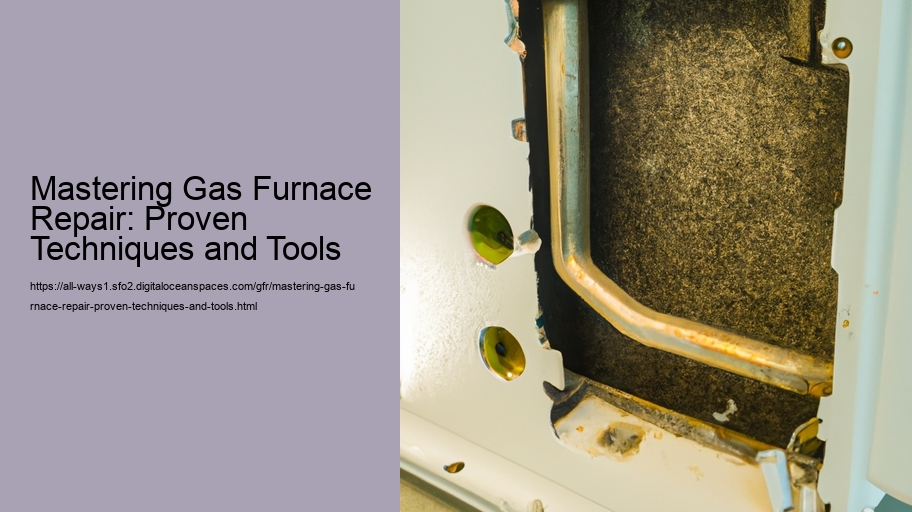

Understanding Gas Furnace Components and Their Functions

Mastering the art of gas furnace repair is crucial for ensuring a warm and safe home during the chilly months. Contact All-Ways Heating & A/C for gas furnace repair services . To excel in this craft, it's essential to have a clear understanding of the various components that make up a gas furnace and the functions they serve. Only with this knowledge can one diagnose issues accurately and employ proven techniques and tools to fix them.

The heart of a gas furnace is its burner, where natural gas or propane mixes with air to produce a controlled flame. energy rebate consultation This combustion process is initiated by an ignition system, which can be either a standing pilot light or an electronic igniter, depending on the age and model of the furnace.

Once ignited, the heat from the burner warms up a metal heat exchanger. The primary job of this component is to transfer heat from the burning gas to the air without mixing them together. As cold air passes over and around the hot heat exchanger, it heats up before being distributed throughout your home via ductwork.

An essential safety feature in any gas furnace is its flame sensor or thermocouple. This small but vital component detects whether or not a flame is present when the gas valve is open. chimney inspection If no flame exists, it signals to shut off fuel supply thus preventing harmful gases from accumulating.

Airflow within a furnace is driven by an inducer fan (also known as draft inducer) which ensures exhaust gases are vented out through a flue pipe safely away from indoor spaces. Atop that same exhaust pathway might sit another safety device: pressure switches that detect blockage in vent pipes triggering shutdown if necessary.

Another indispensable player in our heating ensemble is the blower motor which propels warmed air into living spaces while pulling cooler air back for reheating - maintaining constant circulation for even temperature distribution.

Furnace operation wouldn't be complete without control systems like thermostats which act as conductors for this thermal orchestra – instructing when to start or halt heating based on user-set temperatures.

In modern furnaces, circuit boards play an increasingly critical role by serving as brains behind operations; monitoring stages of heating cycles and coordinating responses between different components.

To maintain optimal performance levels regular maintenance including inspecting filters (which cleanse circulating air), checking condensate lines (removing water produced during heating) should become routine practices alongside more technical repairs requiring specific tools such as multimeters for electrical testing or manometers for measuring gas pressure.

Mastering gas furnace repair involves familiarizing oneself with each instrument in our metaphoric 'heating band', learning their individual tunes but also how they harmonize together creating warmth that turns houses into homes. With practiced technique guided by an understanding of these intricate parts and their symphony of functions - anyone can become proficient at keeping their home's hearth humming through even coldest winters.

Diagnostic Strategies for Identifying Common Gas Furnace Issues

Mastering Gas Furnace Repair: Proven Techniques and Tools

The ability to effectively diagnose and repair a gas furnace is an indispensable skill for HVAC technicians. A well-functioning gas furnace is essential for maintaining a comfortable living environment during colder months, and common issues can arise that require prompt attention. Mastering the use of proven techniques and tools to troubleshoot these problems is crucial in delivering timely and efficient repairs.

Diagnostic Strategies:

Initial Assessment - The diagnostic process begins with an initial assessment of the furnace's overall condition. This includes checking for any visible signs of damage or wear, listening for unusual noises, and noting any abnormal smells. This first step can provide immediate clues as to what might be malfunctioning within the system.

Understanding Error Codes - Modern gas furnaces are often equipped with onboard diagnostics which will display error codes when there is a problem. Familiarizing oneself with these codes and their meanings enables technicians to quickly pinpoint issues. It's important to have access to the manufacturer's manual or error code charts specific to the model being worked on.

Electrical Testing - Many furnace problems are related to electrical components such as thermostats, igniters, sensors, or control boards. Using multimeters to check voltages, continuity tests to ensure circuits are complete, and amperage checks on motors can help identify electrical faults that may be preventing normal operation.

Component Inspection - Regularly examining components prone to failure like the heat exchanger, blower motor, belts, burners, and pilot light can save time by identifying physical defects that could lead to bigger issues if left unaddressed. Visual inspection should also assess airflow blockages due either from clogged filters or ductwork obstructions.

Combustion Analysis - To ensure proper fuel burning within the furnace, combustion analyzers measure gases like carbon monoxide (CO), oxygen (O2), and nitrogen oxides (NOx). Imbalances detected by this tool may indicate incomplete combustion due to improper air-to-fuel ratios or venting issues which need correction for safe operation.

Pressure Checks - Gas pressure measurements are vital since too much or too little pressure can affect furnace performance significantly. Manometers are used both at the supply line entering the home as well as at points within the furnace itself ensuring that appropriate pressures are maintained according to specifications.

Temperature Measurements – Checking temperature differentials across various parts of the system using infrared thermometers or probe thermometers helps verify that heat exchange processes occur correctly without overheating or inefficiency in heat distribution throughout living spaces.

By utilizing a systematic approach combining visual inspections with advanced tools for electrical testing and component analysis alongside knowledge of typical wear patterns in gas furnaces; technicians can swiftly diagnose common problems ranging from faulty ignition systems through inadequate ventilation resulting from accumulated debris obstructing airflow pathways inside ductwork layouts designed specifically around each unique installation scenario encountered within residential settings where safety remains paramount above all else when performing maintenance tasks associated directly involving combustible materials like natural gas utilized widely across North America today despite rising alternative energy solutions gaining popularity among eco-conscious consumers looking towards greener futures ahead.

Proven Techniques for Troubleshooting Electronic Ignition Systems

When it comes to mastering gas furnace repair, understanding and troubleshooting electronic ignition systems is crucial. These modern systems have replaced the older pilot-light-based ignitions and are central to the efficient operation of contemporary gas furnaces. The benefits of electronic ignition systems include improved safety, greater reliability, and better energy efficiency.

The first step in mastering these repairs is familiarizing oneself with the two common types of electronic ignition systems: intermittent pilot and hot surface ignition. The intermittent pilot system uses a high-voltage electrical spark to ignite the gas only when the furnace is activated, while the hot surface ignition system utilizes a resistively heated element to ignite the gas.

Proven techniques for troubleshooting these systems begin with safety precautions. Always ensure that power is turned off before you start working on any components of an electronic ignition system. Next, visually inspect for obvious signs of wear or damage such as cracked ceramics or burned-out elements.

For intermittent pilot systems, one should check if the spark generator is operational by observing if it produces a spark during a call for heat. If there's no spark, the problem may lie within the ignition module or control board, which will need testing with a multimeter.

Hot surface ignitors require checking their resistance using a multimeter to determine if they fall within an acceptable range specified by the manufacturer; typically 40-90 ohms for silicon carbide and 11-17 ohms for silicon nitride ignitors. A reading outside this range indicates that replacement is necessary.

Additionally, issues might arise from faulty flame sensors which can prevent furnaces from staying lit due to safety protocols that assume unburned gas is present without proper detection of a flame.

Mastering Gas Furnace Repair: Proven Techniques and Tools - pilot light adjustment

- electrical wiring inspection

- ignition system repair

Troubleshooting also involves examining pressure switches and venting pathways since improper drafting caused by clogged vents or faulty switches can lead to ignition failures. Ensuring that all airways are clear and switches operate as designed helps maintain consistent performance.

It's important not just to know how each component works but also understand how they interact within the system. Furnace cycles must be followed logically – from thermostat signals through limit controls and safety switches before reaching ignition components – ensuring each part functions effectively in sequence.

Finally, having access to service manuals specific to the make and model being worked on cannot be overstated; these documents provide invaluable information including specifications, error codes interpretations, diagnostic procedures, wiring diagrams which make troubleshooting more straightforward.

In conclusion, becoming adept at repairing electronic ignition systems requires knowledge of different types of ignitions used in modern furnaces as well as familiarity with various components involved in creating and detecting flames efficiently. By utilizing proven troubleshooting techniques – such as systematic inspections, electrical measurements with multimeters and logical analysis of operating cycles – along with specialized tools like manometers for measuring draft pressures or combustion analyzers for verifying proper combustion - technicians can accurately diagnose problems leading to effective repairs thereby ensuring safe operation and optimal performance of gas furnaces.

Step-by-Step Guide to Repairing Mechanical Failures in Gas Furnaces

Mastering Gas Furnace Repair: Proven Techniques and Tools

The intricacies of gas furnace repair can be a daunting prospect for the uninitiated, yet with the right knowledge and tools, even a novice can tackle common mechanical failures. The following step-by-step guide is designed to empower homeowners and budding technicians alike to confidently address issues that may arise with their gas furnaces.

Understanding Your Furnace:

Before attempting any repairs, familiarizing yourself with your specific model of gas furnace is crucial. Obtain the make and model number, usually found on a plate or sticker inside the door of the unit. With this information in hand, you can access the owner's manual which often includes troubleshooting tips specific to your furnace.

Safety First:

When dealing with any type of repair involving natural gas and electricity, safety must be your paramount concern. Always turn off power to the unit at the breaker box and close the gas valve before beginning work. Ensure proper ventilation in your workspace to prevent any buildup of natural gases.

Tools You'll Need:

A well-equipped toolbox will make repairing your gas furnace much easier. Basic essentials include screwdrivers, wrenches, a multimeter for electrical testing, a manometer for measuring gas pressure, needle-nose pliers, an adjustable wrench for dealing with gas fittings, and protective gear such as gloves and eyewear.

Common Mechanical Failures & Repair Techniques:

1. Ignition Failure:

If your furnace fails to ignite when it should be heating, first check if the pilot light (in older models) or electronic igniter (in newer models) is functioning correctly. For pilot lights that won’t stay lit after several attempts or electronic igniters not glowing hot enough to light the burner assembly—replacement may be necessary.

2. Faulty Thermostat:

Sometimes what seems like a major issue could simply stem from thermostat malfunctions due to dead batteries or improper settings. If replacing batteries doesn't resolve this issue then wiring checks should follow; ensure all connections are secure.

3. Blower Motor Problems:

Listen for unusual noises which could indicate motor bearings needing lubrication or more serious issues requiring motor replacement. Checking capacitor integrity using a multimeter will also help determine if it’s contributing to blower motor failures.

4. Dirty Filters or Blocked Airflow:

Before delving into more complex areas of repair always check air filters—a clogged filter restricts airflow causing undue stress on other components leading them toward failure faster than normal wear would dictate; replace as needed which is generally every 3 months depending on usage levels within home environments where dust accumulates quickly versus cleaner homes where changing might only need occur semi-annually.

5. gas furnace installation Heat Exchanger Issues:

Cracks in heat exchangers are serious as they can allow carbon monoxide into your home; look for signs like soot around seams or water collecting beneath heat exchanger compartments signaling potential problems that require professional attention immediately due its dangerous nature regarding health risks involved when inhaling toxic fumes produced during combustion processes happening inside furnaces themselves while operating normally otherwise unnoticed without regular maintenance checks performed annually at minimum by certified HVAC technicians trained specifically in identifying these types hazards associated with residential heating systems relying on natural gases as fuel source powering them through winter months especially where temperatures drop below freezing points causing equipment work harder maintain comfortable living conditions indoors year round regardless external weather patterns affecting different regions across country varying degrees day night cycles changing seasonally over time eventually wearing down parts over years use necessitating replacements keep running efficiently safely long term basis planning ahead accordingly budget

Calibration and Maintenance Best Practices for Peak Performance

Calibration and maintenance are indispensable aspects of ensuring peak performance in gas furnace repair. Mastering the intricacies of these processes is crucial for technicians seeking to provide reliable, efficient, and safe heating solutions. pilot light adjustment By adhering to best practices in both calibration and maintenance, professionals can extend the lifespan of a gas furnace, minimize downtime, and guarantee optimal operation.

Calibration is a delicate procedure that involves adjusting the furnace's control systems to ensure accurate function. This process ensures that all sensors, igniters, and burners operate within manufacturer specifications. Proper calibration is especially critical for modern high-efficiency furnaces with complex electronic controls that manage fuel input and air mixture to optimize combustion efficiency.

One best practice in calibration includes using precision instruments to measure gas pressure and airflow rates. Technicians must also be vigilant about inspecting thermocouples or flame sensors which play an essential role in safety by detecting whether the burner has ignited correctly. If these components are not functioning properly or if they detect a false reading due to miscalibration, it could lead to improper firing or even dangerous conditions such as gas leaks.

In addition to precise calibration, consistent maintenance is another pillar of peak performance for gas furnaces. Regularly scheduled maintenance helps identify potential issues before they become major problems. This involves cleaning filters, checking heat exchangers for cracks, inspecting ductwork for obstructions or leaks, verifying thermostat functionality as well as examining electrical connections for signs of wear or corrosion.

Best practices dictate that technicians should follow a comprehensive checklist during routine inspections. This checklist might include tasks such as lubricating moving parts like blower motors and fans; testing safety controls; measuring voltage and current on motors; checking belts for tension and wear; cleaning burners; checking condensate drains; inspecting pilot lights or ignition systems on older units; and ensuring proper ventilation.

Moreover, effective communication with clients about their equipment's status after each service call is also part of exemplary maintenance culture. Educating customers on how they can contribute to maintaining their system—such as changing filters regularly—can go a long way towards preventing unnecessary service calls.

Investment in continuous training for technicians cannot be overstated when discussing best practices in both calibration and maintenance work. Staying abreast of technological advancements in diagnostic tools like combustion analyzers is necessary for accurate adjustments according to manufacturers' latest recommendations.

Finally yet importantly is adherence to safety protocols at every step: from turning off power before beginning any repair work to checking for carbon monoxide leakage after completing jobs—it’s important that technicians maintain a commitment to operational safety above all else.

In conclusion, mastering gas furnace repair demands rigorous attention to calibration and regular preventative maintenance. By embracing these best practices—and coupling them with professional development opportunities—technicians will provide superior service while upholding industry standards leading not only towards peak performance but also fostering trust among clientele seeking warmth through colder seasons.

Selecting the Right Tools and Equipment for Efficient Gas Furnace Repair

Mastering Gas Furnace Repair: Proven Techniques and Tools

Selecting the Right Tools and Equipment for Efficient Gas Furnace Repair

In the realm of gas furnace repair, efficiency is not just a buzzword—it's a necessity. Technicians who can swiftly diagnose issues and effectuate repairs with precision are in high demand. The key to such proficiency lies not only in one's skills but also in the selection of appropriate tools and equipment.

A seasoned HVAC technician understands that having an extensive toolbox is like having an encyclopedia of solutions; each tool serves a specific purpose, ensuring that any problem encountered can be addressed effectively. The first step towards efficient repair work is to carry standard hand tools such as wrenches, screwdrivers, pliers, and hammers which are indispensable for basic tasks like loosening fasteners or adjusting components.

However, when it comes to gas furnaces, there are specialized instruments needed to ensure safety and accuracy. A multimeter becomes crucial for electrical diagnostics—measuring voltage, current, and resistance within the furnace's circuitry. Similarly, a manometer is used to check gas pressure—a critical factor for a safe operation.

An inspection camera or a borescope allows technicians to peer into tight spaces and assess internal parts without dismantling the entire unit—an invaluable resource when searching for hidden faults. Meanwhile, combustion analyzers measure flue gases to determine if the furnace burns fuel efficiently and safely—a must-have tool for modern diagnostics.

For more advanced troubleshooting steps involving flame sensors or igniters, one might require specific electronic testers designed for these components. These highly sensitive devices help pinpoint malfunctions that might not be readily apparent through visual inspection alone.

The importance of proper equipment extends beyond diagnostic tools; safety gear is equally essential. Protective eyewear shields against debris during cleaning or repairs while heat-resistant gloves protect hands from hot surfaces. Additionally, using reliable leak detectors ensures that no hazardous gas escapes go unnoticed during or after repair work.

Moreover, investing in quality brands pays dividends over time as they tend to offer better performance and durability—a vital consideration given the demanding nature of HVAC work. Being equipped with well-crafted tools reduces downtime caused by equipment failures mid-repair.

Efficient gas furnace repair also necessitates up-to-date knowledge about smart thermostats and their integration with modern heating systems since these technologies are becoming commonplace in households. Understanding how these devices communicate with furnaces helps technicians perform seamless installations or troubleshoot connectivity issues quickly.

heating system replacement

It’s important too not forget about software resources which have become an integral part of HVAC operations—from mobile apps that assist in calculating BTU requirements to programs that provide interactive wiring diagrams helping technicians visualize complex electrical connections within furnaces.

Ultimately selecting the right tools isn't just about filling a toolbox; it's about building an arsenal of resources poised to tackle any challenge with confidence—balancing between tried-and-true methods along with embracing technological advancements—all aimed at mastering the art of gas furnace repair.

Advanced Tips for Seasoned Technicians: Enhancing Efficiency and Longevity

Advanced Tips for Seasoned Technicians: Enhancing Efficiency and Longevity in Mastering Gas Furnace Repair

For seasoned technicians, mastering the art of gas furnace repair is not just about knowing the basics; it’s also about refining their techniques and employing the right tools to enhance efficiency and ensure the longevity of heating systems. Over time, skilled technicians develop a wealth of experience that allows them to troubleshoot complex issues, perform repairs with precision, and deliver service that stands the test of time.

One advanced tip for experienced technicians is to adopt a systematic approach to diagnosis. This means going beyond obvious symptoms and understanding the intricate workings of modern gas furnaces. For instance, when faced with an ignition failure, a seasoned technician would consider all potential causes such as faulty igniters, defective flame sensors, or inadequate gas supply before jumping into a replacement. This thoroughness not only solves problems more effectively but also prevents unnecessary component replacements.

Efficiency in repairs can be enhanced through continuous learning and staying updated with the latest technological advancements in furnace design and diagnostics tools. Newer models often come equipped with sophisticated electronics that require specialized knowledge to interpret error codes accurately. Investing time in manufacturer training sessions or certification courses ensures that technicians are well-versed in these nuances.

Another area where experienced technicians can shine is by perfecting their use of tools essential for gas furnace repair. From digital manometers for measuring gas pressure to combustion analyzers for assessing exhaust gases, having a deep understanding of these instruments' capabilities can greatly improve diagnostic accuracy. Moreover, using high-quality tools reduces the risk of damage during repairs and increases reliability.

Proactive maintenance practices constitute another cornerstone of enhancing furnace longevity. Seasoned technicians know that addressing small issues before they escalate can prevent catastrophic failures down the line. Regularly inspecting components such as heat exchangers for cracks or checking blower motors for optimal performance helps maintain system integrity.

In addition to technical skills, effective communication plays an integral role in successful gas furnace repair. Advanced technicians should convey complex information clearly to customers, explaining why certain repairs are necessary and how they contribute to the overall health of their heating system. This builds trust and assures homeowners that their investment in professional services yields tangible benefits.

Lastly, adopting safety protocols cannot be overstressed when working on gas furnaces due to inherent risks like carbon monoxide leaks or fire hazards. Even veterans in the field must rigorously adhere to safety standards by ensuring proper ventilation during repairs or testing safety devices like carbon monoxide detectors after completing work on a system.

In conclusion, seasoned technicians looking to enhance their efficiency and promote longevity in mastering gas furnace repair must combine comprehensive knowledge with meticulous technique while fully leveraging advanced tools at their disposal. Continuous education and adherence to best practices round out this skill set which ultimately leads not only to superior service but also extends the life span of heating systems entrusted into their expert care.