Verify the Thermostat Settings

When it comes to ensuring the proper functioning of a gas furnace, one of the fundamental steps is to verify the thermostat settings.

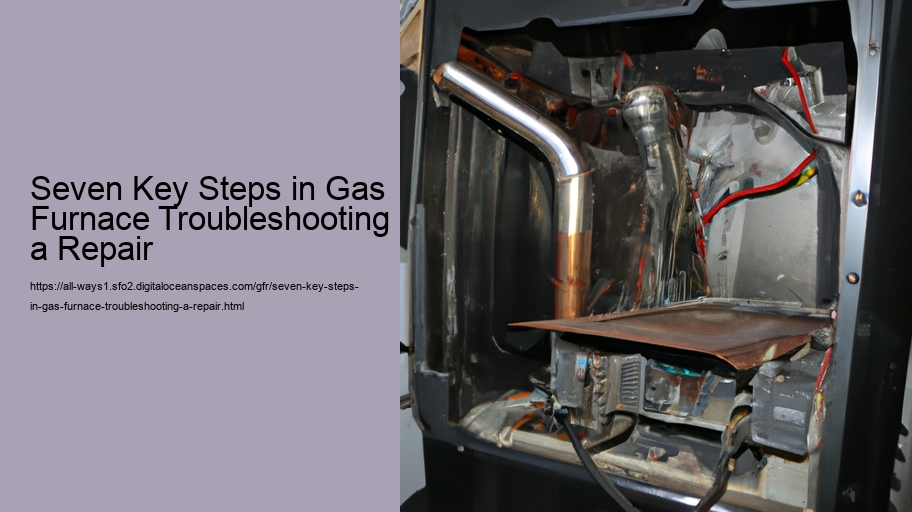

Seven Key Steps in Gas Furnace Troubleshooting a Repair - heating system replacement

- pressure switch calibration

- limit switch testing

The thermostat serves as the command center for your heating system. Get in contact with All-Ways Heating & A/C for gas furnace repair services in Everett WA. It dictates when the furnace turns on and off based on the temperature settings you input. If these settings are incorrect or if there's an issue with the thermostat itself, your furnace may not operate as expected.

To begin this step, first ensure that the thermostat is set to "heat" mode. This may seem obvious, but it's a common oversight that can lead to confusion about why a furnace isn't producing heat. After confirming that it's set correctly, check the desired temperature setting against the current room temperature displayed on the thermostat. If the room temperature is below what you've set, but there’s no response from your furnace, then further investigation into thermostat function is warranted.

Next, inspect whether the programmable settings (if available) are correct for your current needs. Many modern thermostats allow homeowners to create schedules for their heating systems to conserve energy while they're away or asleep but still maintain comfort when they're home and awake. Misprogramming can result in an improperly heated home at unexpected times.

Another key aspect is checking whether power is being supplied properly to your thermostat. If batteries power it, make sure they aren’t dead or dying—this could cause erratic behavior or complete failure of your heating controls. For wired thermostats, verify that all wires are securely connected and that there are no signs of damage or corrosion which might impede their function.

Advanced troubleshooting may involve ensuring that there are no loose wires within your thermostat housing if you feel comfortable opening it up; otherwise consult with a professional technician who can safely perform this task for you.

If after verifying all these factors you determine there’s something amiss with either your settings or with how your thermostat responds—or doesn't respond—it may be time to consider replacing this critical component of your home's heating system.

In conclusion, verifying thermostat settings should never be overlooked when addressing problems with a gas furnace. It’s a straightforward yet vital step in diagnosing issues before moving onto more complex components within the heating system such as ignitors, flame sensors, and control boards. Properly set and functioning thermostats contribute significantly toward achieving optimal comfort levels in our homes while also playing an important role in energy efficiency.

Check the Furnace Filter Condition

When troubleshooting a gas furnace, one of the crucial steps that should not be overlooked is checking the condition of the furnace filter. This seemingly simple task can have profound effects on both the performance and longevity of your heating system.

The furnace filter plays an essential role in maintaining indoor air quality by trapping dust, dirt, pet dander, and other airborne particles.

Seven Key Steps in Gas Furnace Troubleshooting a Repair - air filter replacement

- furnace troubleshooting

Moreover, when airflow is restricted due to a clogged filter, it can lead to a range of issues such as uneven heating across different rooms or even causing the heat exchanger to overheat and shut down prematurely. This safety mechanism protects against potential damage but also leaves you without heat until the issue is resolved.

Checking the furnace filter should be a regular part of your home maintenance routine. To do this effectively:

1. First ensure that you turn off power to your furnace for safety reasons.

2. Locate the access panel where the filter is housed; this is typically found along the return duct or at the entrance to the blower chamber.

3. Remove the existing filter carefully – if it's reusable, you'll want to clean it according to manufacturer instructions; if it's disposable, note its size so you can replace it with a new one of correct dimensions.

Inspecting your furnace filter gives you an opportunity not only to clean or replace it if necessary but also provides insight into possible issues affecting indoor air quality. For instance, excessive amounts of pet hair or dust could indicate that additional measures are needed such as improved sealing around doors and windows or addressing ventilation concerns.

In conclusion, while checking the furnace filter might seem like a small step in gas furnace troubleshooting and repair process, its impact on system efficiency and reliability cannot be overstated. Ensuring that this vital component is in good condition will help keep your gas furnace running smoothly and efficiently throughout those cold winter months while keeping energy costs in check and prolonging life span of your entire heating system.

Inspect the Pilot Light and Ignition System

When troubleshooting and repairing a gas furnace, one of the crucial steps that should never be overlooked is the inspection of the pilot light and ignition system. This step is vital because it directly relates to the fundamental operation of your furnace – its ability to produce heat.

The pilot light in older gas furnaces serves as a small flame that ignites the main burner. It must remain lit for your furnace to start properly. Inspecting it involves checking that this flame is present, steady, and has the correct blue color with perhaps just a hint of yellow at the tip. If you find that it's out or flickering excessively, there could be an issue with blockages in the pilot tube, drafts disrupting the flame, or problems with thermocouple positioning or functionality.

Modern gas furnaces might not have a standing pilot light; instead they use electronic ignition systems. These can take on different forms such as hot surface igniters or intermittent pilots. For these types of systems, inspection means ensuring that electrical connections are secure and components aren't damaged or dirty. An intermittent pilot system uses a high voltage electrical spark to ignite the gas when heat is called for by the thermostat - so look out for sparks failing to generate or issues with sensors that detect whether ignition has occurred.

No matter what type of ignition system your gas furnace uses, safety should always be your primary concern during inspection. Ensure all power and gas supply lines are shut off before beginning any kind of diagnostic checkup on your heating equipment.

During this step of troubleshooting, if you do encounter issues like a malfunctioning pilot light or faulty ignition system components, these may be signs pointing towards necessary repairs or replacements. Sometimes cleaning certain parts can solve a problem; however, more complex situations such as replacing a defective ignition module will require professional attention.

In conclusion, inspecting the pilot light and ignition system is indispensable when maintaining effective function in your gas furnace.

Seven Key Steps in Gas Furnace Troubleshooting a Repair - heating system replacement

- heating system replacement

Evaluate Electrical Connections and Circuit Breakers

When embarking on the troubleshooting and repair of a gas furnace, one critical aspect that must not be overlooked is the evaluation of electrical connections and circuit breakers. This step is essential because a gas furnace relies on electricity for various functions, including the ignition process, running the blower motor, and powering the control board.

To begin with, safety is paramount. Ensure that power to the furnace is turned off before starting any inspection or repairs. Once safety precautions are in place, you can proceed to examine the electrical components.

Start by visually inspecting all wiring connections. Look for signs of wear, fraying, corrosion, or any other damage that could compromise conductivity or pose a fire hazard. Verify that all connections are secure and tight as loose connections can lead to intermittent power issues which may cause erratic furnace operation.

Next, focus on the circuit breakers related to your heating system. It's essential to confirm they are in good working order since they protect your home from electrical overloads by breaking the circuit if excessive current is detected. A tripped breaker might indicate an overload or an issue with the furnace itself. programmable thermostat installation If a breaker has tripped, reset it once and monitor to see if it trips again – this could signal an underlying problem requiring further investigation.

Additionally, consider examining any fuses associated with your heating system as these serve a similar protective purpose as breakers but need replacement when blown rather than simply being reset.

It's also crucial to check voltage levels where appropriate using a multimeter; this ensures that each component receives the correct amount of power needed for optimal performance. For instance, insufficient voltage supply to a blower motor could result in poor airflow through your home’s ductwork.

Lastly, don't forget about ground wires which help prevent electric shock by providing a safe path for stray voltage. Ensuring proper grounding helps protect both your equipment and household from potential electrical hazards.

In summary, evaluating electrical connections and circuit breakers forms an integral part of gas furnace troubleshooting and repair. By methodically inspecting these elements for integrity and functionality along with adhering strictly to safety protocols you set up a strong foundation towards restoring your gas furnace back to its reliable state while maintaining household safety against potential electric risks.

Assess the Blower Motor and Belt Tension

Troubleshooting a gas furnace can often feel like an intimidating task, but by breaking down the process into key steps, it becomes more manageable. One of these crucial steps involves assessing the blower motor and belt tension. This is vital because the blower motor is responsible for circulating air throughout your home, and if it isn't functioning properly or the belt connecting it to the blower wheel is too loose or tight, your furnace might fail to heat your space effectively.

When you approach this step in gas furnace troubleshooting, begin with safety first. Ensure that all power to the furnace is turned off before you start any inspection or repair work. Once that's done, proceed to locate the blower compartment; it's typically found in the lower part of the furnace.

Start by visually inspecting the blower motor for obvious signs of wear and damage. Look out for corrosion, overheating discoloration, or debris accumulation which could impede its operation. blower motor repair If everything looks normal on initial inspection, move on to check whether there are any strange noises when it operates – these could indicate internal issues that might require professional attention.

Next up is checking belt tension if your system uses a belt-driven motor. The belt should have a slight give when pressed — about half an inch of play is usually ideal — but it shouldn't be so loose that it slips nor so tight that it causes excessive wear on bearings and other components. Inspect its surface as well; look for cracks or fraying which suggest that it needs replacing.

If adjustments are needed for optimal performance, most systems will allow you to loosen the motor mount to change belt tension. After making adjustments or changing a worn-out belt (as necessary), turn on the power briefly and observe if there's an improvement in how smoothly and quietly the blower motor runs.

Remember also to consider lubrication as part of maintenance on older models with non-sealed bearings; newer models typically have sealed bearings which don’t need manual lubrication.

In conclusion, proper assessment of the blower motor and belt tension forms an essential part of gas furnace troubleshooting and repair. A well-maintained blower ensures efficient airflow through your heating system, contributing significantly towards maintaining a comfortable indoor environment during cold weather months. Regular checks can prevent unexpected breakdowns and potentially costly repairs down the line while ensuring longevity of your heating system’s components.

Examine the Condensate Drain for Clogs

When troubleshooting and repairing a gas furnace, one of the essential steps you should never overlook is examining the condate drain for clogs. This step, though seemingly minor, can be crucial to ensuring the efficient operation and longevity of your heating system.

The condensate drain is an integral part of a high-efficiency gas furnace. During the heating process, these furnaces produce condensation – a byproduct of combustion when water vapor in the exhaust gas cools below its dew point. The resulting liquid needs to be safely transported away from the furnace to prevent it from causing damage or affecting performance.

Clogging in the condensate drain can occur due to various reasons such as accumulation of debris, mold growth, or even mineral deposits from the water itself. If not addressed promptly, a blocked condensate line can lead to water backing up into the furnace or spilling into your home, which could cause significant damage over time. It may also trigger safety devices that shut down your furnace to prevent further issues.

To examine the condensate drain for clogs effectively:

1. Begin by locating the drain line; this is typically a PVC pipe running from your furnace to a floor drain or other disposal area.

2. Check any visible parts of the pipe for signs of leakage or moisture that could indicate an existing blockage.

3. Inspect both ends of the line - where it connects to your furnace and where it disposes of the water - for any obstructions.

4. In some cases, you might need to disconnect sections (if possible) and use tools like a wet/dry vacuum to clear out any material causing blockages.

5. If accessible, check and clean out any traps or U-bends in which debris commonly accumulates.

6. For stubborn clogs deeper within lines that are not easily removed with simple manual methods, consider using compressed air or specialized cleaning solutions designed for clearing HVAC drains.

After addressing any potential blockages:

1. Ensure that all connections are secure if you had previously disconnected anything during your inspection.

2. Test run your furnace and observe if there's proper drainage happening without leaks around connections.

3. Continuously monitor over several days especially when your system is under heavy use because sometimes symptoms might reoccur indicating incomplete removal of clog-causing agents.

By performing routine checks on your gas furnace’s condensate drain as part of regular maintenance, you can prevent many common problems associated with drainage issues before they escalate into costly repairs or cause downtime during cold weather when reliability matters most.

Remember that while examining and potentially unclogging a condensate drain is something many homeowners can do on their own with basic tools and safety precautions in place; more complex situations may require professional assistance from certified HVAC technicians who have experience dealing with such systems safely and efficiently.

Test Safety Switches and Controls

One of the fundamental aspects of maintaining a gas furnace is ensuring its safety features are functioning correctly. In the context of troubleshooting and repairing a gas furnace, there are seven key steps that technicians follow to diagnose and fix issues. Among these crucial steps is the testing of safety switches and controls, which serves as an important safeguard against potential hazards.

Safety switches and controls in a gas furnace serve as critical checkpoints that prevent accidents such as gas leaks or fires. These components include limit switches, pressure switches, flame rollout switches, and ignition failure controls. Each switch has a specific role in monitoring conditions within the furnace to ensure safe operation.

The limit switch monitors the temperature inside the heat exchanger to prevent overheating. If temperatures exceed safe levels, this switch will shut off the burner to avoid damage or potential fire risks. The pressure switch checks for proper airflow; it confirms whether the draft inducer fan is drawing enough exhaust gases out of the furnace. Any blockage or malfunction can cause dangerous fumes like carbon monoxide to build up inside a home.

Flame rollout switches act as sentinels in case flames escape from their designated combustion area—indicating potential cracks or blockages within the heat exchanger. Lastly, ignition failure controls ensure that unburned gas does not accumulate by shutting down fuel supply if ignition doesn't occur within certain timeframe.

Testing these safety components involves simulating conditions that should trigger them or using specialized equipment to measure their responsiveness accurately. A technician may manually reset some of these devices to test their functionality after confirming they were triggered for valid reasons.

For instance, if a limit switch was tripped due to overheating, before resetting it, one must find out why overheating occurred—perhaps due to dirty filters restricting airflow or blockages in ventilation ducts—and remedy those issues first.

It's worth noting that bypassing safety switches for extended diagnostics can be done by experienced technicians under controlled conditions but should never be considered a permanent solution nor attempted by unqualified individuals because it could lead to severe hazards.

In essence, testing safety switches and controls is an indispensable step not just in troubleshooting but also in ensuring ongoing operational integrity of a gas furnace system. This procedure protects both homeowners from potentially life-threatening situations and preserves the longevity of their heating systems by preemptively identifying minor problems before they escalate into major ones. Proper attention to these safeguards reinforces trust between service providers and customers while contributing positively towards energy efficiency and environmental stewardship by preventing wasteful consumption or harmful emissions.